4 Ways IIoT is revolutionizing the Pharma Industry

Complex supply chains, finicky chemical processes, and stringent quality control is a large part of the Pharma business. Drugs have to be made safely, efficiently and at scale with correct measures and reliable quality.

What pharma fails to realize is that using manufacturing processes that are decades out of date, and which are being phased out in comparable industries is not enough to compete with the worldwide market. They need to invest more time, effort, and money into the digitalization of their business.

You will also find interesting: Top IoT Trends To Follow In 2022

This is where Industrial IoT comes into action! IIoT holds tremendous potential to revolutionize the pharma industry. It can automate pharmaceutical manufacturing, address various challenges in the discovery of drugs and remotely monitor patients, and more.

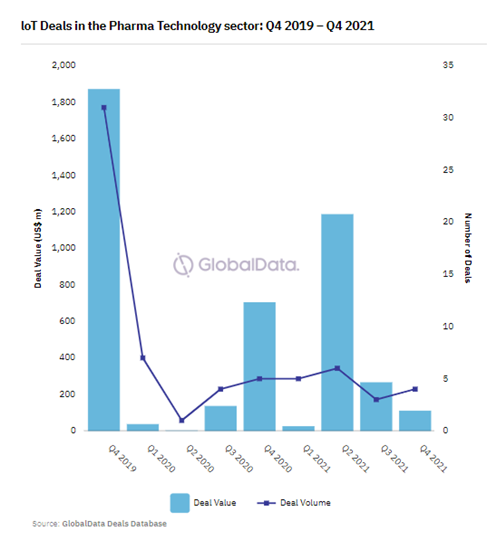

In fact, the Global IoT in Healthcare Market size is forecast to grow from USD 60.83 Billion in 2019 to USD 260.75 Billion by 2027, delivering at a CAGR of 19.8% through 2027. The below graph shows the number of deals currently happing in the pharma sector that involves IoT or similar technologies over the past nine quarters.

With the rapid proliferation of emerging technologies like Artificial Intelligence and Machine Learning in the Pharmaceutical industry, IoT is keeping a close eye on. This article intends to provide an insight into how the Industrial Internet of Things or IoT 4.0 will revolutionize Pharmaceutical sectors.

Pharma 4.0: A newer term, broader scope!

Pharma 4.0 is the framework of the pharmaceutical industry incorporating digital strategies to the unique contexts of manufacturing. In simpler terms, it means more connectivity and transparency, better productivity, simplified compliance, and improvements through the product lifecycle. Manufacturers can have better control over operations and quality, make faster decisions, and respond to the problems as they emerge.

IIoT in Pharma Manufacturing: Taking smart strides.

- Data Connectivity and Analytics

One of the biggest challenges of pharma companies is also one of the simplest – Lack of connectivity. This is neither as facetious nor as trivial as it may sound. Pharma companies generate plenty of data on their process yet many can’t make this data remotely accessible across the organization. Making it extremely difficult to optimize processes, improve manufacturing quality and implement a strategic plan to win the market.

IIoT platform gives every user access to the data to perform their role. They can remotely access multiple structure data sets simultaneously instead of just a single production process. It provides a holistic view into the production process transforming the entire operation with a centralized, structured, remote data hub.

With the IIoT platform, pharma companies can go beyond just connectivity. They can also generate reports for internal or cross-departmental meetings as everyone can access the same information. Teams can also easily track KPIs, expedite daily tasks, and receive updates with just a few clicks, increasing work quality and productivity.

You will also find interesting: How is Industrial IoT Making Manufacturing Safe?

- Digital Twins

A digital twin is a virtual representation of a physical asset like a machine or a device, built to reflect the data, processes, and operations of the asset. With IIoT, digital twins provide visibility into the full lifecycle of the product, unlock deeper operational intelligence in the processes, and optimize maintenance.

It is especially beneficial for producing batch products in pharmaceuticals as manufacturers can understand the impact of each production step. They can track partially build products on the supply chain and isolate damaged ones before it’s too late.

Digital twins also help in reducing the number of required process performance qualification (PPQ) runs and setting a robust control strategy. It can also organize bioprocess development, suggest experimental designs, and manage new knowledge. This helps to improve margin, cut process development costs, and save millions.

- Managing and Controlling Quality

Using an IIoT platform, engineers and technical leads can take the help of reporting tools to easily identify batch variability. It also helps them uncover which process variables have the greatest impact on product quality and which need to be handed over to operation teams.

Such transparency and traceability make it easier to adhere to regulatory requirements or adjust to changing compliance guidelines. It also makes it easier to monitor drug production and storage environments such as temperature, humidity, radiation, and light in real-time without any manual intervention, achieving improved drug quality, safety, and quality of care.

- Better planning and quicker time to market

Leadership teams can leverage real-time data reports across value chain components for generating valuable insights and making near real-time decisions. They can easily access data such as feedback and changes related to drug research, efficacy, adoption, patient outcomes, etc., and plan production processes accordingly.

And not just that, it can be also useful during drug launch, drug pricing, and drug marketing-related strategy development improving efficiency and optimizing the time to market.

The Road Ahead: Future of IIoT in Pharma

IIoT might be still at its nascent stages of development but its impact on the pharma industry is indisputable. Integration IIoT can result in better production processes, decreased costs, and a better experience for both industry leaders and customers alike. However, this promise of digital transformation requires meticulous planning, strategy, and implementation.

With so many IIoT vendors and solutions already crowding the marketplace, you need a partner who builds you a digital transformation roadmap considering your enterprise needs. At iLink, we help organizations to transform their business needs through smart IoT-based solutions and stay ahead in a highly competitive environment.

If you think your pharma industry could benefit in a big way from leveraging IIoT, we are here to help further.

Related content: